spray polyurethane foam thickness test|polyurethane foam spray sampling : distributor This guidance document was prepared by the Spray Foam Coalition of the American Chemistry Council’s Center for the Polyurethanes Industry. It is intended to provide general information . Resultado da Sudeste. 636 members. Canal da região do Rio de Janeiro, São Paulo , Espírito Santo e Minas Gerais.

{plog:ftitle_list}

http://www.burikko.net. A Manga Burikko (漫画ブリッコ?) foi uma revista de mangá hentai com foco no lolicon publicada por Byakuya Shobo em Tóquio entre 1982 a 1985 no .

Once the physical attributes of the two SPF’s are understood, we can start to look at specific applications to assess the potential risks and . See moreThe intent of this guideline is to provide usable, implementable information on acceptable uses of ocSPF and ccSPF in specific applications in residential construction. For that purpose, each of the above potential applications will be considered within a . See more

In combination with where in the thermal envelope the particular insulation is to be placed, the climate-zone where the subject building is to be constructed must be considered. For the purposes of this analysis, the main issues are wet versus dry, and hot versus . See moreThe insulation levels provided by ocSPF are typically adequate to provide a high-level of thermal performance given the relatively low delta-T between inside and outside. Excellent air . See moreThis guidance document was prepared by the Spray Foam Coalition of the American Chemistry Council’s Center for the Polyurethanes Industry. It is intended to provide general information .

The R-value of spray foam insulation ranges from 3.5 to 7 per inch thickness. For open-cell spray foam the R-value is approximately 3.5 whereas for closed-cell spray foam it is 6. Spray foam insulation thickness. .Spray Polyurethane Foam (SPF) Basics. Whether retro-fitting a home or choosing insulation when building a new one, spray polyurethane foam (SPF) insulation is among the best ways to increase energy efficiency and improve comfort. . Air barrier at full wall thickness: Higher strength and rigidity: Lower strength and rigidity: Resists water .%PDF-1.5 %µµµµ 1 0 obj >>> endobj 2 0 obj > endobj 3 0 obj >/ExtGState >/XObject >/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 .

Test Method Test Condition Result Air Barrier Certification ASTM E 283 plywood decks are rated to 190 psf . when adding more foam thickness to achieve the desired R-value. APPLICATION PASS THICKNESS: Spraying foam will generate heat. Foam which . polyurethane spray foam. The B-11-017 drum isWhat is Spray Foam? Spray polyurethane foam (SPF) is a spray-applied plastic that can form a continuous insulation and air sealing barrier on walls, roofs, around corners, and on all contoured surfaces. It is made by mixing and reacting unique liquid components at the job site to create foam. The liquids reactCLOSED-CELL SPRAY POLYURETHANE FOAM IAPMO ES #0146 APPROVALS / COMPLIANCES • 2021, 2015, 2012, 2009 International . a machine with 260 feet of hose should have a dynamic spray pressure of 1360 psi. PASS THICKNESS JM Corbond IV may be applied in a single pass from a minimum of 0.5”to a maximum of 4". . with accepted test methods .

We'll show you the proper technique for spraying polyurethane. Applying it evenly and smoothly without leaving streaks or bubbles can be tricky. We will guid.

spray polyurethane foam installation

Spray polyurethane foam (SPF) insulation is a highly effective and versatile insulating material for buildings. . Connect hoses securely and test spray to calibrate foam output; Adjust pressure and temperature for ideal foam consistency; Keep gun perpendicular to surface at 6-12 inches distance; . Adjust foam thickness and formulas to .Spray Polyurethane Foam (SPF) products are an ideal choice for consumers looking to ensure their homes . thickness of RSI 1.8 (R 10.2). Typically product performance can exceed RSI 2.0 (R 11.4) at 50 mm. [1]" . LTTR test value results per the 2003 version of CAN/ULC S770 (CAN/ULC S770-03) tend to be higher than testing done per later .for the Spray Polyurethane Foam Industry SPFA-126 To download copies of this publication, visit www.sprayfoam.org. . the temperature transmission fire test and the integrity fire test of NFPA 275 NFPA 275 requires two (2) tests: . Particleboard thickness varies with code ¼ inch (6.4 mm) 3/8 inch (9.5 mm) 3/8 inchTypical areas where spray polyurethane foam is applied are: . Property FOAMSULATE Closed Cell TEST; R-VALUE: 6.9 @ 1" ASTM C 518: CORE DENSITY: 2.0 LB / Cubic Foot: ASTM D 1622: CLOSED CELL CONTENT > 90%: ASTM D 6226: SOUND TRANSMISSION COEFFECIENT: 41: . 1883 Btu/ft2 Per Inch Of Thickness: NFPA 285: Pass: Compliant For .

Maximum Thickness Limitations For Cured Foam Maximum thickness limitations for cured spray polyurethane foam can be found in reports from ICC-ES, as well as in techni-cal specifications from spray foam manufacturers. According to the ICC-ES report for BioBased 501 (ESR-1383, issued January 1, 2006), “BioBased 501 spray foam insulation,Spray Polyurethane Foam - Exotherm vs. Thickness Spray polyurethane foam (SPF) can be formulated for application in a wide variety of physical and environmental situations. SPF manufacturers often adjust the reaction rate (“speed”) of their foam systems to accommodate different application conditions. Spray foams designed for cold weather .

Property and Test Method Value mX 2030 mX 2045 Ambient (Substrate) Temperature Range, °F 30-70 (30-60) 45-95 . Maximum foam thickness with code-approved thermal barrier . STYROFOAM Brand Spray Polyurethane Foam contains isocyanate, hydro uorocarbon blowing agent and polyol. Read all the instructions and (M)SDS carefully before use.

If the design calls for greater thickness of foam plastic insulation, greater thicknesses of SPF can be tested (covered with a thermal barrier) in a small room corner test such as NFPA 286 (with the acceptance criteria of Section 302.9.4) can be used to achieve code approvals of foam plastics. . (including spray polyurethane foam) used in .Table 6: Medium Density Spray Polyurethane Foam Insulation Product Property Test Standard Test Standard Title Unit Requirement Min. Max. Flame Spread Characteristics ASTM E84 – 12c Standard Test Method for Surface Burning Characteristics of Building Materials n/a n/a 75 Thermal Transmission ASTM C177 – 10 Standard Test Method3 of 3 BUIDI ISUATI TCICAL BULLTI %FDFNCFS 8, 201 xternal Visit our website at www.JM.com or call 800-654-3103| Building Insulation Division P.O. Box 5108 | Denver, CO 80217-5108 Technical specifications as shown in this literature are . The two main chemical components of Spray Polyurethane Foam are polyol resins and isocyanate. These chemicals are mixed in the right proportion to produce an effective spray foam product. The ratio and quality of these chemicals can impact insulation properties. . The production of spray foam insulation thickness R-value as high as R5.6 to R7 .

11 Hope Road, Suite 111, #308 Stafford, Virginia 22554. Contact Us. [email protected] © 2024 Spray Polyurethane Foam Alliance.Closed Cell Spray Polyurethane Foam has been recognized for years for its ability to remain in place during high wind events. However, its use as a structural enhancement material for roof . (Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference) testingProperty SealTite Test R-Value 6.9 @ 1" 21 @ 3" ASTM C-518 . Code (IRC) require that spray polyurethane foam be separated from the . approved alternative. Gypsum board at a minimum thickness of ½" is a Code-prescribed 15-minute thermal barrier. The following products when The thickness or thermal resistance of the spray foam is specified by the International Residential Code (IRC) based on climate zone and thickness of the wall framing . Spray polyurethane foam can also be applied to the interior of rigid foam exterior sheathings such as foil faced isocyanurates and extruded polystyrene (XPS).

The rule is not to spray foam if the air temperature is not more than 5 degrees from the current dew point. •Apply foam to dry surfaces. Application to damp or wet surfaces can be seen and will effect the foam physical properties. Inspection of the bottom portion of core samples and slit samples should not show blown or sporadic cellsHistorically, spray polyurethane foam (SPF) met code by being applied behind gypsum or covered with approved, add-on thermal barriers, i.e., cellulosic and cementitious materials. SPF could also comply with code through “exception” methods using the lower-level ignition barrier approval (method two) or special approval testing (method three).

In addition to its fire certification, the HEATLOK HFO Pro spray foam system offers a number of key additional performance attributes and benefits. Offering an R-value of 7.4 at 1-inch installed thickness and an R-value of 11 at 1.5-inch installed thickness, the 2.2-pound spray foam notably provides a higher yield. Many builders use spray polyurethane foam as an air barrier, raising the question: How thick does the spray foam layer have to be to stop air flow? . In the test, a free-standing sheet of foam is tested to see whether it woks as an air barrier. That would be the relevant test if you were spraying the foam onto an air-permeable material to .What is Spray Foam? Spray polyurethane foam (SPF) is a spray-applied plastic that can form a continuous insulation and air sealing barrier on walls, roofs, around corners, and on all contoured surfaces. It is made by mixing and reacting unique liquid components at the job site to create foam. The liquids react

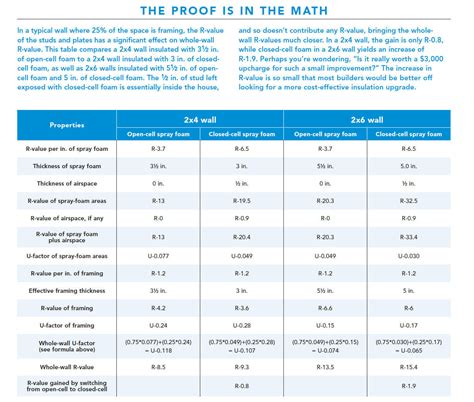

spray foam rating chart

09vip là kênh cá cược chất lượng quốc tế. Tại đây cung cấp vô vàn sản phẩm cá cược thú vị cùng nhiều phần thưởng cao khiến người chơi đứng ngồi không yên.

spray polyurethane foam thickness test|polyurethane foam spray sampling